Retrofit Emission Control Device (RECD) 50 kVA to 4000 kVA

Certified Solutions for Cleaner Diesel Power

At Saranya, we believe in sustainable power, without compromise. Our advanced filter technology is engineered to Retrofit Emission Control Device (RECD) for DG set, effectively transforming them into eco-friendly power sources.

By capturing harmful emissions directly at the source, we significantly reduce air pollution and support your commitment to a cleaner, healthier future.

Trusted by industries, commercial establishments, and institutions across the country, we provide durable, efficient, and government-certified solutions that meet the latest environmental regulations, making us one of the most trusted Retrofit Emission Control Device Manufacturers in India.

Features

RECD Features

Eco-Friendly Retrofit

Instantly reduces carbon emissions from any genset.

High Capture Efficiency:

Captures up to 90% of pollutants, significantly reducing PM, HC, and CO.

Cost-Effective & Low Maintenance:

Efficiently designed for minimal upkeep and long-term use.

Modular Design:

Compact and easily installed on top of any existing genset.

Verified Performance:

Tested and certified for performance and efficiency, adhering to environmental standards.

Passive Regeneration:

Process takes care of self cleaning.

Design:

Engineered & Designed for easy installation.

Testing:

Tested under ISO 8178-5 mode D2 cycle from CPCB accredited Lab upto 800 kW.

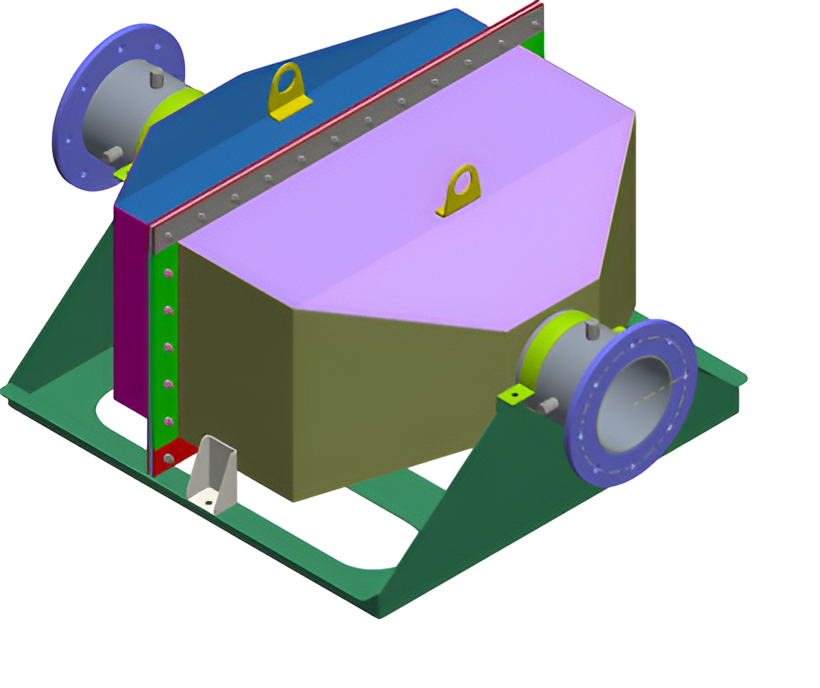

RECD Physical Structure

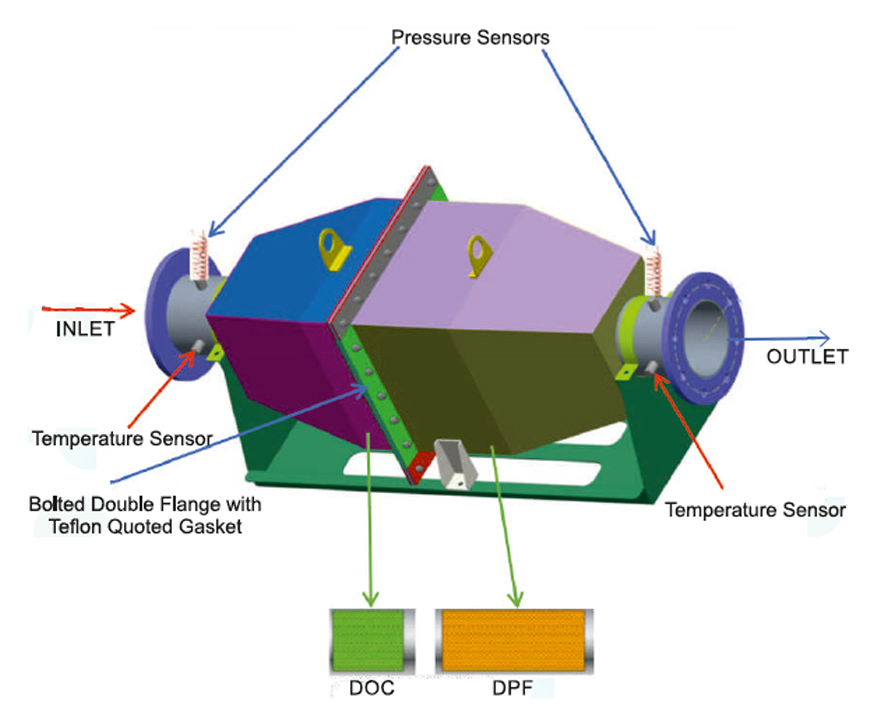

Diesel Oxidation Catalyst (DOC) Working Priciple

DOC consists of a Ceramic honeycomb structure called a substrate or catalyst. The interior surfaces are coated with catalytic metals. DOC converts exhaust gas pollutants into harmless gases by means of chemical reaction. DOC can assist the DPF to remove the filtered carbon deposits. When the DOC is around 190°- 200°C, the NO in the exhaust gas is oxidized to form NO2 which helps in regeneration at DPF.

DOCS are typically flow-through structure, allowing exhaust gas to flow through the catalyst.

Diesel Particulate Filter (DPF) Working Principle

Wall-flow diesel particulate filters (DPFs) remove particulate matter in diesel exhaust by filtering exhaust from the engine. The structure of a wall-flow DPF is similar to that of an oxidation catalyst, except every other channel is blocked with a dense plug. To remove the soot, raw exhaust enters an open channel at the front of the DPF. The walls of the filter are engineered for the gases to pass through but trapping the soot particles inside. The DPF contains a thin layer of catalyst that chemically converts the soot particles to carbon dioxide. The catalyst also allows the DPF to function as an oxidation catalyst, reducing HC and CO in addition to PM. Once converted, the gases pass through the filter's porous walls and into a much cleaner exhaust stream. Since the DPF gets deposited overtime, accumulated particulate matter will get burnt off and the filter is cleaned, or "regenerated" When the exhaust temperature goes above 190 Deg C

DOCS are typically flow-through structure, allowing exhaust gas to flow through the catalyst.

Emission Control Technologies

Retrofit Emission Control Devices (RECDs) consist of Diesel Oxidation Catalyst (DOC) and Diesel Particulate Filter (DPF), which work in tandem within the RECD to ensure diesel gensets and engines meet environmental regulations while promoting cleaner air and healthier communities.

A Diesel Oxidation Catalyst (DOC) consists of a ceramic honeycomb substrate, whose interior surfaces are coated with precious catalytic metals. DOCS are typically a flow-through structure, allowing exhaust gas to flow through the catalyst.

Working Priciple

- As exhaust gases pass through the DOC’s flow-through structure, the catalyst triggers a chemical reaction that converts harmful pollutants such as carbon monoxide (CO), hydrocarbons (HC), and some particulate matter (PM) into less harmful gases like carbon dioxide (CO₂) and water vapor (H₂O).

- At operating temperatures of 200–250°C, the DOC oxidizes nitrogen monoxide (NO) into nitrogen dioxide (NO₂). This NO₂ is critical for assisting the regeneration process in the downstream Diesel Particulate Filter (DPF), helping it burn off the accumulated soot.

Diesel Particulate Filter (DPF)

A Diesel Particulate Filter (DPF) is designed to trap and eliminate soot and ash from the exhaust of diesel engines. It uses a wall-flow design, in which alternate channels of a ceramic honeycomb structure are plugged at opposite ends.

Working Principle

- Exhaust gases enter the open channels of the DPF and are forced through the porous ceramic walls, which trap particulate matter (PM), including soot and fine ash, while allowing filtered gases to exit.

- A catalytic coating on the walls helps convert soot into carbon dioxide (CO₂).

- At exhaust temperatures above 190°C, a process called regeneration occurs, during which trapped soot is burned off, restoring filter capacity and maintaining efficiency.

Applications

- Diesel Gensets in Commercial Buildings

- Infrastructure & Construction Sites

- Manufacturing Plants & Industrial Zones

- Hospitals & Pharma Industries,

- Data Centers, IT/ITES

- Garment Manufacturing

Product Features

- DOC - DPF System with passive Re-Generation.

- Maintenance free design - Maintenance/Cleaning required if the DG sets are run on less than 30% load. RECD fitted engines requires to be run on 50% and above load once a while to achieve the desired exhaust temperature to activate passive Re-Generation.

- Industry best 2 Years Warranty on RECD - (Except Electrical Panel and sensors which would be 6 Months)

- Designed for 15 years / 15,000 hours of operation

- Components sourced from local MNC's

- Proven & Globally accepted technology , similar type of technology being used by several Engine Manufacturers globally.

- ZERO back pressure by RECD (As per ARAI Test Report)

- In line with CPCB latest norms with On Board Diagnostic Panel safety systems

- Very high efficiency PM reduction (92.6%) along with HC and CO above 70%

- Very less maintenance

- Compact and easy to install. Operator warning system enabled

- Separate land space/ concrete foundation not required

- Installation of RECD can be Horizontal or Vertical position

- Service Support by SGPL Network

- PLC with HMI based Control Panel for Temperature and Pressure monitoring and data logging

- Color display informing of system status and operational conditions.

- RECD is suitable across various Engine brands and models

- Buy-Back facility available, in case the DG set is sold or scrapped

- Can be installed on any other equivalent rating genset, in case the genset is replaced

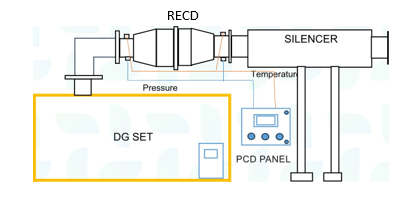

Typical Installation

Dimensions - Weight

RECD Dimensions - Weight

| Sl.No | kVA Rating | Dimensions LxWxH-MM | Weight-Kgs |

|---|---|---|---|

| 1 | 50-82.5 | 750x400x400 | 65 |

| 2 | 100-160 | 950x860x500 | 100 |

| 3 | 180-280 | 950x860x500 | 165 |

| 4 | 320-380 | 1200x860x1100 | 220 |

| 5 | 500-650 | 1200x1240x1100 | 280 |

| 6 | 750-910 | 1200x1310x1100 | 310 |

| 7 | 1110-1250 | 1200x1700x1100 | 400 |

| Above 1250 - As per site requirement | |||

| Dimensions & Weight are subject to change due to continuous product improvements | |||

Do's & Don'ts for Operation & Maintenance

Please adhere to the following guidelines for healthy engine and RECD operation.

- Avoid running the DG set on no-load daily, if necessary, run the DG set on at least 35% load till the engine attains its optimal temperature.

- Carbon accumulation in the exhaust will build up if the DG set is operated on No Load or Low load.

- RECD works at its optimal if the engine is operated at a minimum of 35% load factor

- RECD to be installed closer to the engine or before Silencer to avoid clogging of RECD with Mineral / Glass wool which is used in the silencer for internal lining for sound attenuation.

- The loose fibres of Mineral / Glass clogs the RECD which leads to engine performance deterioration, and would lead to replacement of RECD.

RECD Installation Recommendations:

- Before installation of RECD run engine on min. 80% load and record exhaust back pressure & temperature Before installation of RECD run engine and record dB level

- Run and check the engine for lube oil, fuel, exhaust gas & coolant leaks. Rectify all the leaks before installation of RECD

- Run engine on load & confirm that no excessive blowby or crankcase pressure condition exists Check lube oil consumption record of engine from log book & ensure it is in limit

- Refer to the RECD Drawing for Model, dimensions & weight of device to select size of supports & lifting equipment.

- Mount the PCD panel on concrete slab/floor to avoid damage due to vibration

- Mount the PCD panel away from heat/hot manifolds

- The sensor harness to be routed, secured with clamps & clips

- RECD should be mounted before silencer

- RECD should be located nearest to the engine

- Ensure proper steel support or bottle spring support to RECD to avoid load on pipes & flanges

- All the exhaust pipe engine till RECD must be cladded with high quality thermal insulation

- Record parameters on load after RECD installation

Need a Custom Solution?

Every site is different. Our team offers site assessments, customization options, and installation support to ensure optimal performance and compliance.

Contact us today to learn how our RECD can help your operation stay ahead in the clean energy transition.